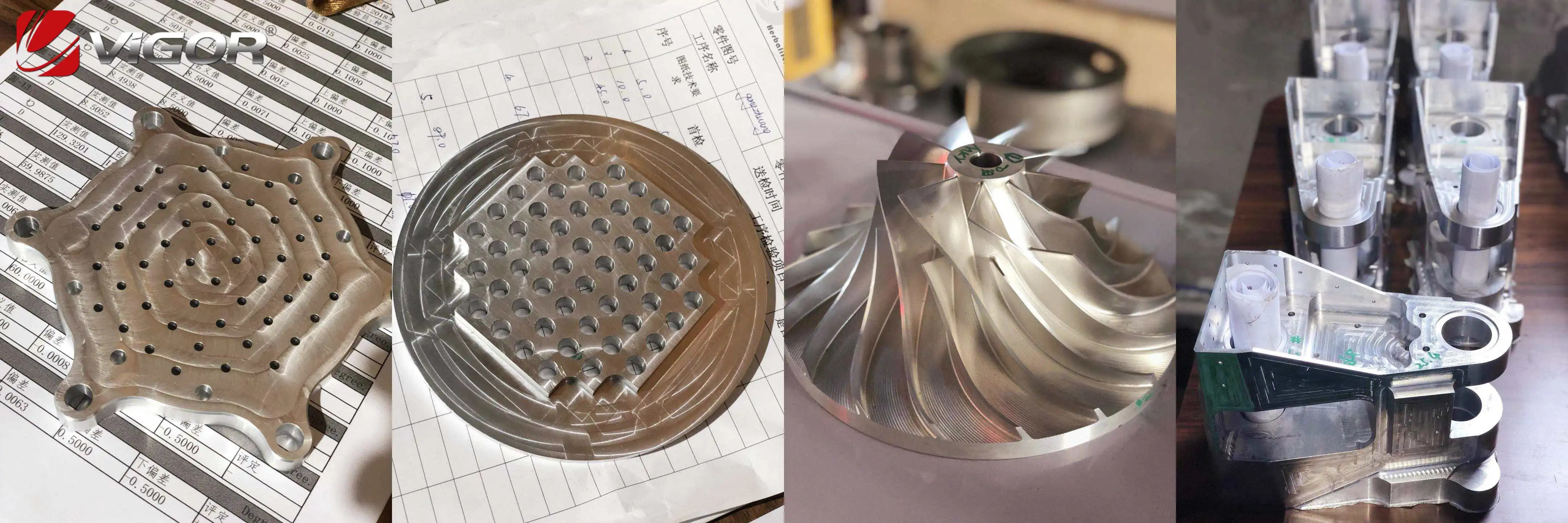

5 Axis Machining Parts

5 Axis Machining Parts Manufacturer

In today's demanding manufacturing landscape, precision and complexity are paramount. From aerospace components to intricate medical devices, the need for parts with intricate geometries and tight tolerances is ever-growing. This is where the power of 5 axis machining parts comes into play. At [VIGOR INNO-TECH Limited], we specialize in delivering high-quality, custom-manufactured 5-axis machined parts that meet the stringent requirements of diverse industries.

1.Why Choose 5 Axis Machining?

Unlike traditional 3-axis machining, which operates along the X, Y, and Z axes, 5-axis machining adds two rotational axes (A and C). This allows for simultaneous movement of the cutting tool and the workpiece, enabling the creation of complex shapes and intricate details with incredible precision and efficiency.

2.Key Parameters of Our 5 Axis Machining Parts

We understand the critical importance of delivering parts that meet your exact specifications. Our 5-axis machining capabilities offer exceptional control over:

| Materials | We work with a wide range of materials, including aluminum alloys, stainless steel, titanium alloys, high-temperature alloys, and composites |

|

| Tolerances | Our advanced machinery and skilled technicians ensure tight dimensional and geometric tolerances, meeting your most demanding requirements | |

| Surface Finish | We achieve superior surface finishes through optimized tool paths and cutting strategies | |

| Part Complexity | From intricate curves to complex internal features, we can manufacture parts with unparalleled complexity | |

| Batch Sizes | We accommodate both small batch prototyping and large-scale production runs |

3.The 5 Axis Machining Process: Precision in Action

Our 5 Axis Machining Parts machining process begins with a thorough understanding of your design and requirements. We utilize advanced CAD/CAM software to create optimized tool paths and simulate the machining process, ensuring accuracy and efficiency. Our skilled machinists then execute the program on our state-of-the-art 5-axis machining centers, meticulously monitoring the process to guarantee quality.

Rigorous Testing and Quality Assurance

To ensure the highest level of quality, we employ a comprehensive range of testing equipment, including:

Coordinate Measuring Machines (CMMs): For precise dimensional measurements.

Surface Roughness Testers: To verify surface quality.

Non-Destructive Testing (NDT): To detect internal flaws without damaging the part.

4.Applications of 5 Axis Machined Parts

Our 5 Axis Machining Parts services cater to a wide range of industries, including:

Aerospace: Manufacturing complex engine components, airframe structures, and turbine blades.

Automotive: Producing intricate engine parts, transmission components, and tooling.

Medical Devices: Creating precise surgical instruments, implants, and diagnostic equipment.

Mold Manufacturing: Producing complex molds for injection molding and die casting.

Energy: Fabricating components for power generation equipment and oil and gas exploration.

Robotics: Manufacturing intricate robotic arms, end-effectors, and sensor housings.

5.Why Choose us?

We are committed to providing our customers with exceptional quality, competitive pricing, and on-time delivery. Here's what sets us apart:

|

|

Advanced Technology: We invest in the latest 5-axis machining technology to ensure superior precision and efficiency. Experienced Team: Our team of skilled engineers and machinists has extensive experience in 5-axis machining. Comprehensive Services: We offer a full range of services, from design assistance to post-processing and finishing. Secure Packaging: We ensure that your parts are carefully packaged and protected during transit. Global Reach: We serve customers worldwide with efficient logistics and reliable shipping. Our Factory: We welcome you to visit our state-of-the-art facility and witness our capabilities firsthand. |

6.FAQ

Q: What file formats do you accept for CAD drawings?

A: We accept a wide range of formats, including STEP, IGES, and DXF.

Q: What is your typical lead time for 5-axis machined parts?

A: Lead times vary depending on the complexity and quantity of the parts. We will provide a detailed quote and estimated delivery date upon request.

Q: Do you offer post-processing services?

A: Yes, we offer a range of post-processing services, including anodizing, electroplating, and heat treatment.

7.Contact Us

Ready to discuss your 5 Axis Machining Parts needs? Contact us today at info@castings-forging.com to learn more about our capabilities and request a quote. We look forward to partnering with you!

hotTags : 5 Axis Machining Parts,China, suppliers, manufacturers, factory, foundry, customized, buy, quotation, low price, high quality, high accuracy, high performance, free sample,accurate,OEM.