Turbocharger Impellers

Production process: 5 Axis Machining Center

Material: Al-Alloy, Ti-Alloy, Stainless Steel (material grade as per customer’s request)

Turbocharger Impellers

Welcome to VIGOR INNO-TECH Limited, your trusted partner in advanced engineering solutions. Our turbocharger impellers are designed to enhance the performance and efficiency of your engines, whether you're in the automotive, industrial, marine, or aerospace sectors. With a focus on precision, durability, and innovation, we deliver high-quality impellers that meet the most stringent industry standards.

1.Parameters

Our turbocharger impellers are engineered to meet the highest standards of performance and reliability. Here are some key parameters:

| Material | Available in Al-Alloy, Ti-Alloy, and Stainless Steel, with material grades tailored to your specific requirements |

| Design | Integral impeller design ensures optimal performance and durability |

| Machining | Precision 5-axis machining center for high accuracy and consistency |

| Tangential Speed | Capable of achieving high tangential speeds, essential for maximizing air compression |

| Environmental Conditions | Designed to operate under high temperature, high pressure, and corrosive environments |

| Surface Finish | Enhanced surface roughness for improved aerodynamic performance |

| Mechanical Properties | Optimized for strength, fatigue resistance, and wear resistance |

| Tolerances | Optimized for strength, fatigue resistance, and wear resistance |

2.Working Process

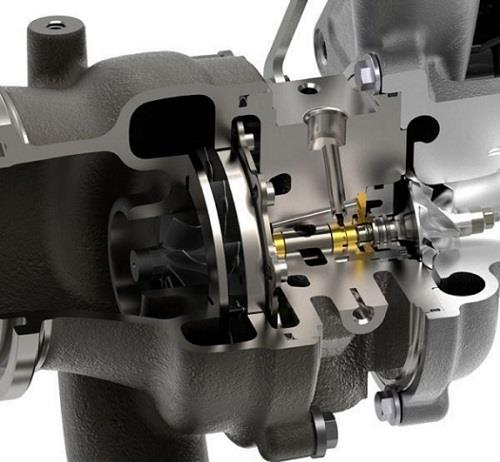

The turbocharger impeller is the heart of the turbocharging system. Here’s how it works:

Intake: Air enters the turbocharger through the intake port.

Compression: The impeller, driven by the exhaust gases, spins at high speeds, compressing the air.

Flow: The compressed air is then forced into the engine's cylinders, increasing the amount of oxygen available for combustion.

Power Output: The increased oxygen leads to more complete combustion, resulting in higher power output and improved fuel efficiency.

The impeller's complex structure and high-speed operation make it a critical component in the turbocharging process. Our impellers are designed to handle these demanding conditions, ensuring reliable performance and longevity.

3.Testing Equipment

At VIGOR INNO-TECH, we use state-of-the-art testing equipment to ensure the quality and performance of our product:

|

Dynamic Balancing Machines: To ensure smooth operation and minimize vibrations. High-Speed Spin Testers: To simulate real-world operating conditions and verify performance. Material Testing Equipment: To confirm the strength, hardness, and other mechanical properties of the materials used. Surface Roughness Gauges: To measure and optimize the surface finish for better aerodynamics. Temperature and Pressure Chambers: To test the impellers under extreme conditions. |

|

Dynamic Balancing Machines: To ensure smooth operation and minimize vibrations.

High-Speed Spin Testers: To simulate real-world operating conditions and verify performance.

Material Testing Equipment: To confirm the strength, hardness, and other mechanical properties of the materials used.

Surface Roughness Gauges: To measure and optimize the surface finish for better aerodynamics.

Temperature and Pressure Chambers: To test the impellers under extreme conditions.

4.Turbocharger Impellers Applications

Our turbocharger impellers are versatile and suitable for a wide range of applications:

| Application | Turbocharger |

| Production Process | 5 Axis Machining Center |

| Material | Al-Alloy, Ti-Alloy, Stainless Steel (Material grade as per customer's request) |

|

|

The impeller is the heart of turbocharger. An impeller is on a turbocharger’s rotor and usually has a very complicated structure. When the turbocharger operates, the impeller will press as much purified air into the cylinder, transforming it into kinetic energy to improve the engine’s output. During the process, the impeller spins fast, and the tangential speed of the rim is fast. So the flow situation in the impeller is complicated, and usually under high temperature, high pressure, and corrosive environment. Integral impeller design and quality have a crucial impact on the turbocharger’s performance. Despite a reasonable design, machining precision and technical requirement are important as well. |

5.Why Choose Us?

Our Advantages:

Expertise: Our team of experienced engineers and technicians ensures that every impeller meets the highest standards of quality and performance.

Customization: We offer custom solutions to meet your specific requirements, from material selection to design modifications.

Innovation: We stay at the forefront of technological advancements, incorporating the latest materials and manufacturing techniques.

Quality Control: Rigorous testing and inspection processes guarantee that our impellers perform reliably in even the most demanding conditions.

Customer Support: Our dedicated customer service team provides comprehensive support, from initial consultation to post-sale maintenance.

Logistics and Packaging:

Packaging: Our impellers are carefully packaged to ensure safe transportation and handling.

Shipping: We offer flexible shipping options to meet your delivery needs, with reliable logistics partners worldwide.

Our Factory:

State-of-the-Art Facilities: Our modern facilities are equipped with the latest manufacturing and testing equipment.

ISO Certification: We are ISO certified, ensuring consistent quality and compliance with international standards.

6.FAQ

Q: What materials do you use for your turbocharger impellers?

A: We use high-strength, high-temperature resistant, and corrosion-resistant materials such as Al-Alloy, Ti-Alloy, and Stainless Steel. The material grade can be customized to meet your specific requirements.

Q: How do you ensure the quality of your impellers?

A: We use advanced testing equipment and rigorous quality control processes to ensure that every impeller meets the highest standards of performance and reliability.

Q: Can you provide custom solutions?

A: Yes, we offer custom solutions to meet your specific requirements, from material selection to design modifications.

Q: What is the lead time for custom orders?

A: The lead time for custom orders varies depending on the complexity and volume of the order. We work closely with our customers to provide accurate lead times and ensure timely delivery.

Q: Do you offer after-sales support?

A: Yes, we provide comprehensive after-sales support, including installation guidance, troubleshooting, and regular maintenance.

7.Contact Us

Ready to elevate your engine performance with our high-quality turbocharger impellers? Contact us today at info@castings-forging.com to learn more about our products and services. Our dedicated team is here to help you every step of the way.

hotTags : Turbocharger Impellers,China, suppliers, manufacturers, factory, foundry, customized, buy, quotation, low price, high quality, high accuracy, high performance, free sample,accurate,OEM.