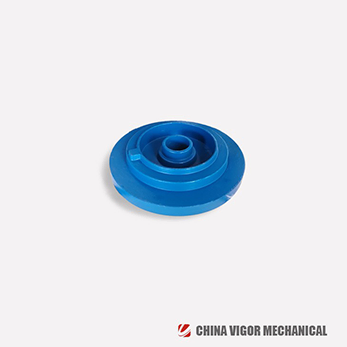

Explosion Proof Motor Casting

Production process: Pre-coated sand casting

Material: Ductile Iron (material grade as per customer’s request)

Tolerance can meet: ISO 8062 CT8 – CT10

Surface roughness can meet: around Ra (μm) 12.5

Explosion Proof Motor Casting Introduction

Explosion Proof Motor Casting are crucial components in various industries where safety is paramount. These castings, often the heart of explosion-proof motors, are designed to prevent sparks and ignition in hazardous environments. At [VIGOR INNO-TECH Limited], we understand the critical role these castings play and are committed to providing high-quality, reliable solutions tailored to your specific needs. This page details our expertise in creating explosion-proof brake motor castings, focusing on the critical aspects that ensure both safety and optimal performance.

Parameters

Choosing the right explosion-proof motor casting depends on several key parameters. Your specific application dictates the necessary specifications. At [VIGOR INNO-TECH Limited], we understand these intricacies. We offer a range of ductile iron (customizable to your material grade requirements) explosion-proof motor castings that adhere to strict industry standards. Key parameters include:

Material: Our ductile iron castings are robust and resistant to corrosion and wear while minimizing potential for internal defects like porosity and shrinkage holes.

Tolerance: We consistently achieve ISO 8062 CT8 - CT10 tolerances, ensuring precise alignment and optimal performance.

Surface Roughness: Our castings boast a surface roughness around Ra (μm) 12.5, enhancing functionality and longevity.

Protection Level: We adhere to the necessary safety standards, ensuring compliance with ATEX and IECEx directives.

Power & Voltage: These critical parameters are determined in consultation with you, ensuring the casting aligns perfectly with your motor's specifications.

| Application | Explosion Proof Brake Motor |

| Production Process | Pre-coated Sand Casting |

| Material | Ductile Iron (Material grade as per customer's request) |

| Tolerance | ISO 8062 CT8 - CT10 |

| Surface Roughness | Around Ra (μm) 12.5 |

The Casting Process: A Detailed Look

Our pre-coated sand casting process for explosion-proof motor components is meticulously crafted to prevent defects. We understand the potential for issues like sand drop defects, slag inclusions, and secondary reactions in ductile iron castings. Our rigorous process addresses these challenges, ensuring a high-quality final product.

Pre-coated Sand Casting: This method enhances the casting's quality and durability.

Defect Prevention: We employ specialized techniques to prevent porosity, shrinkage holes, and hot spot defects, which are crucial for safety in hazardous environments. Our pouring system is designed to minimize these risks.

Post-Casting Processing: Our advanced CNC machining centers, lathes, milling machines, and boring machines provide precision finishing, ensuring precise dimensions and meeting your required tolerances.

Testing Your Confidence: Rigorous Quality Control

We believe in transparency and verifiable quality. Our rigorous quality control process encompasses a range of tests to guarantee the safety and performance of your explosion-proof motor castings:

[List specific testing methods and equipment]: For example: "We utilize advanced X-ray inspection tools to detect hidden defects, ensuring the integrity and safety of each casting."

[Mention specific industry certifications]: "All our explosion-proof motor castings comply with ATEX and IECEx standards."

Explosion Proof Motor Casting Application

Explosion Proof Motor Casting have a lot of spare parts made by casting.

As one of the main features is to avoid any spark during operation, therefore, we developed a special process for the pouring system to avoid sand drop defects, slag inclusion defects, and the defects generated when the secondary reaction of ductile iron in the shells after pouring.

We can also do the finish machining in our workshop with the advanced CNC machining centers, CNC machining lathes, milling machines, boring machines, etc.

Why Choose Us?

Our Advantages

Proven Expertise: [VIGOR INNO-TECH Limited] has a proven track record of producing high-quality explosion-proof motor castings.

Customization: We specialize in offering customized solutions to meet your exact requirements.

Logistics and Packaging:

Our efficient logistics and protective packaging ensure safe delivery of your order.

Factory Overview:

[Brief overview of your factory and production processes.]

FAQ

Q: What certifications do your Explosion Proof Motor Castings hold?

A: Our castings are designed to meet relevant safety certification standards like ATEX and IECEx. We can provide specific certification details upon request.

Q: Can you accommodate large-scale orders for major oil and gas companies?

A: Absolutely. We have the capacity and experience to handle large procurement volumes while maintaining quality and competitive pricing.

Q: Do you offer customized solutions for specific applications?

A: Yes, we work closely with our clients to understand their unique needs and develop customized solutions that meet their application requirements.

Contact Us

Ready to learn more about our Explosion Proof Motor Castings? Contact us today at info@castings-forging.com to discuss your project requirements and receive a personalized quote. Our team of experts is ready to assist you in finding the perfect solution for your needs. We look forward to partnering with you!

hotTags : Explosion Proof Motor Casting,China, suppliers, manufacturers, factory, foundry, customized, buy, quotation, low price, high quality, high accuracy, high performance, free sample,accurate,OEM.