Knowledge

About the Characteristics of Sand Casting Process

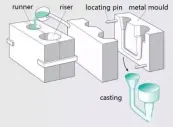

Casting process is a metal hot working process, which involves melting the metal into a liquid state and then pouring it into a pre-prepared mold (mold), allowing it to cool, solidify, and finally form a casting with a certain shape, size and properties. Casting process is an important method of metal forming, which is widely used in industrial production, especially in the manufacture of large, complex or metal parts with specific performance requirements.

The main features of the casting process include

A wide range of materials: almost all metal materials can be molded through the casting process, including iron, steel, aluminum, copper, magnesium, zinc and so on.

Flexible design: The casting process can produce parts with complex shapes and fine contours, and the design freedom is high.

Dimensional accuracy: Through accurate mold design and control, high dimensional accuracy can be obtained.

Production efficiency: The casting process can be mass produced, suitable for large-scale manufacturing.

Cost effective: For large or complex parts, the casting process is often more cost effective than other metal forming methods.

Machinability: Parts after casting usually require further machining to meet end use requirements.

Today, we mainly introduce one of the ten processes of casting, sand casting;

Casting method for producing castings in sand mold. Steel, iron and most non-ferrous alloy castings can be obtained by sand casting.

Technical features

1.Suitable for making a complex shape, especially with a complex internal cavity blank;

2.Wide adaptability, low cost;

3.For some very poor plastic materials, such as cast iron, sand casting is the only molding process to manufacture its parts or blanks.

Welcome to reach out us to communicate about your requirements. Please feel free to call us at 029 81161513 or email us at info@castings-forging.com