Knowledge

Advanced Manufacturing Techniques for Turbocharger Impellers

The evolution of turbocharger impeller manufacturing has transformed dramatically over the years, driven by advancements in precision engineering and the demand for high-performance automotive components. At VIGOR INNO-TECH Limited, with over 18 years of experience in castings and forgings, we leverage cutting-edge technologies such as 5-axis machining centers to deliver high-quality turbocharger impellers efficiently. Through continuous process improvement, expert risk management, and precise quality control, we ensure that each impeller meets stringent performance criteria. Today, we'll explore the advanced manufacturing techniques that enable the production of turbocharger impellers that push the limits of durability, efficiency, and precision.

Precision in Turbocharger Impeller Manufacturing

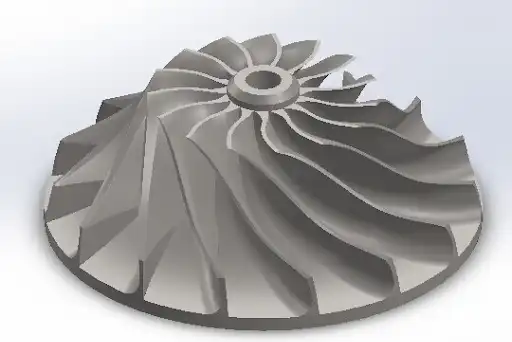

Turbocharger impellers are critical components in turbocharged engines, responsible for compressing air into the combustion chamber, improving engine efficiency, and ultimately boosting vehicle performance. Creating these intricate parts involves a combination of advanced manufacturing technologies, each chosen to optimize performance, material integrity, and precision.

At the heart of this process is 5-axis machining, a technology that enables the production of complex geometries with exceptional accuracy. By allowing the cutting tool to move across five different axes, this method minimizes the need for multiple setups, improving both precision and speed. For impellers, which often feature complex curves and tight tolerances, 5-axis machining is essential for creating the intricate blade designs that optimize airflow.

Additionally, casting and forging techniques play vital roles in the initial production stages, providing a strong foundation for further machining. Forging, in particular, imparts superior strength to the material, which is crucial for components like turbocharger impellers that must endure extreme temperatures and rotational forces.

The Role of 5-Axis Machining in Impeller Production

Understanding 5-Axis Machining

The use of 5-axis machining in turbocharger impeller production unlocks significant advantages. Unlike traditional 3-axis machining, which limits movements to three directions (X, Y, and Z), 5-axis machining allows for more dynamic tool paths by adding rotational movement around the X and Y axes. This added flexibility allows manufacturers to create more complex and precise designs in one setup, enhancing both efficiency and accuracy.

For turbocharger impellers, this advanced machining capability ensures that each impeller blade is sculpted to exact specifications, allowing for optimal airflow and maximum engine performance. The process also reduces the likelihood of errors, such as misalignments, that could impact the impeller's functionality.

Advantages of 5-Axis Machining in Impeller Manufacturing

- Improved Precision and Surface Finish: The ability to machine from multiple angles reduces the need for manual repositioning, resulting in a superior surface finish and fewer imperfections.

- Reduced Lead Time: With fewer setups and more efficient tooling paths, 5-axis machining significantly cuts down on production time.

- Versatility in Material Handling: Whether working with lightweight aluminum alloys or high-strength titanium, 5-axis machining handles diverse materials, ensuring each impeller is crafted to withstand high stress and temperature environments.

Casting & Forging: Foundational Processes for Turbocharger Impeller Manufacturing

Casting Techniques for Turbocharger Impellers

Casting is often the first step in turbocharger impeller production, particularly when dealing with large production volumes. In this process, molten metal is poured into a mold to form the rough shape of the impeller. Once cooled and solidified, the impeller is further refined through additional machining processes.

Common casting methods include sand casting and investment casting, both of which are used for producing impellers depending on the specific requirements of the part. Investment casting, in particular, is favored for its ability to produce high-precision components with excellent surface finishes.

Forging for Enhanced Strength

Forging, on the other hand, is a prevalent choice when strength is of most extreme significance. Amid forging, metal is molded beneath high pressure, which adjusts the grain structure of the material, coming about in a part that is essentially stronger than one delivered by casting alone. This strength is basic in turbocharger impellers, which must withstand high levels of mechanical stress and temperature fluctuations.

Heat Treatment and Surface Finishing

After casting or forging, many turbocharger impellers undergo heat treatment to improve their mechanical properties, such as toughness and fatigue resistance. Heat treatment processes such as tempering and annealing help to ensure that the impeller can withstand the harsh conditions inside a turbocharged engine. Additionally, surface finishing techniques like polishing or coating are applied to further improve the impeller's performance and longevity.

Quality Control and Risk Management in Turbocharger Impeller Production

Importance of Quality Control

In turbocharger impeller production, even minor defects can lead to catastrophic engine failures. That's why robust quality control measures are essential throughout the manufacturing process. At VIGOR INNO-TECH, we implement a comprehensive quality management system that includes non-destructive testing (NDT), dimensional analysis, and material testing. These processes ensure that every impeller meets the highest standards of quality and safety.

Risk Management in Customized Production

Each turbocharger impeller is designed to meet particular execution prerequisites, and as a result, the manufacturing process must be carefully custom-made to minimize dangers. Through our broad involvement in customized parts structure analysis, we can recognize potential weak points in the design and generation handle, permitting us to make alterations that progress execution and decrease disappointment rates.

Continuous Improvement and Innovation

At VIGOR INNO-TECH, we are committed to continuous improvement. Our engineers regularly review and refine our manufacturing processes to ensure that we stay at the forefront of innovation. This ongoing effort not only helps us reduce production costs but also ensures that we can deliver the highest quality turbocharger impellers to our customers, regardless of their specifications.

Conclusion

The manufacturing of turbocharger impellers requests a combination of innovative technology, precise engineering, and a profound understanding of materials and processes. Through the utilize of progressed strategies such as 5-axis machining, casting, forging, and rigorous quality control measures, VIGOR INNO-TECH has the ability to deliver high-performance turbocharger impellers that meet the most requesting details. Our commitment to ceaseless improvement and hazard administration guarantees that we convey parts that not only meet but surpass our customers' expectations.

For more information about how we can assist with your turbocharger impeller needs, don't hesitate to contact us at info@castings-forging.com.

References

1. Manufacturing Processes for Turbocharger Components: A Comprehensive Guide

2. Advances in 5-Axis Machining for Precision Parts

3. Casting and Forging Techniques for Automotive Components

4. Heat Treatment Processes in High-Performance Automotive Parts

5. Quality Control in Precision Engineering: Methods and Applications

6. Risk Management and Defect Prevention in Custom Manufacturing