Knowledge

Applications of Pressure Die Casting

Some of the common applications of pressure die casting are listed below:

1. Automotive components (engine blocks, gearbox cases, and wheel spacers).

2. Consumer electronics (smartphone frames, connectors, and housings).

3. Aerospace parts (actuators, gearbox components, and engine mounts).

4. Lighting fixtures (lamp housings, reflectors, and heat sinks).

5. Power tools (gearboxes, motor housings, and handles).

6. Sporting goods (golf clubs, bicycle frames, and fishing-reel bodies).

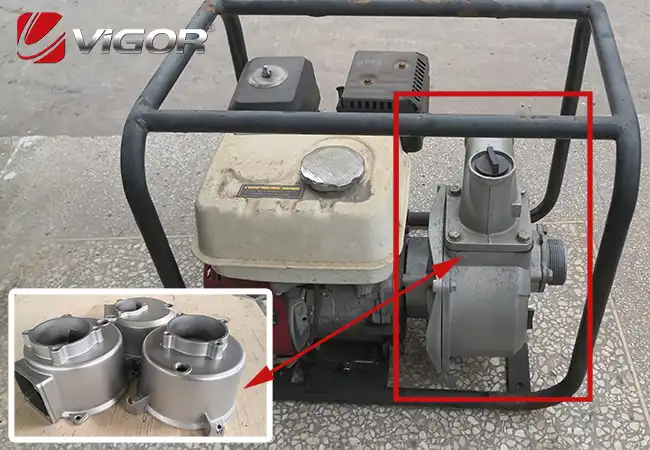

7. Industrial machinery (pumps, valves, and compressors).

8. Electrical components (connectors, switchgear, and enclosures).

9. Furniture hardware (handles, knobs, and frames).

What Are the Advantages of Pressure Die Casting?

1. Some of the benefits and advantages of pressure die casting include:

2. Ideal for high-volume manufacturing.

3. This process produces parts with high precision and consistent dimensions.

4. It enables the casting of complex shapes with intricate details and thin walls.

5. Castings have a smooth surface directly out of the mold.

6. The process can achieve tight tolerances.

7. It has less waste compared to other fabrication methods that involve material removal.

8. A wide range of non-ferrous metals can be used, including: aluminum, zinc, magnesium, and copper alloys.

9. It can produce large quantities of parts in a short time frame.

10. While the initial setup and tooling costs can be high, the per-unit cost significantly decreases for large production runs, making it cost-effective for mass production.

11. HPDC allows for the casting of extremely thin-walled components — as thin as 1 mm.

What Are the Disadvantages of Pressure Die Casting?

While there are several advantages associated with pressure die casting, it also has some drawbacks, such as:

1. The initial costs for tooling and setting up pressure die casting operations are high due to the complexity and precision of the molds required.

2. It’s prone to porosity issues. The rapid cooling and solidification can lead to porosity in the cast parts, which might affect their mechanical strength and integrity.

3. Pressure die casting is generally limited to non-ferrous metals.

4. There are size limitations for cast parts due to the constraints of the die casting machines and the pressure required to fill the mold.

Vigor has been a key player in the machinery industry for many years, providing us with extensive experience in the production and manufacturing of Pressure Die Casting. Our team of technical engineers is committed to ensuring strict adherence to your specific needs, guaranteeing that every aspect of the process is under control. We take pride in our ability to deliver top-quality products and services, and we would be delighted to hear from you if you are interested in our mechanical products. Please do not hesitate to contact us to receive the best quality products and services.