Knowledge

Casting Process Characteristics and Types

The casting process is a manufacturing method in which molten metal is poured into a mold, which is cooled and solidified to form a casting of the desired shape and size. This is a very old and widely used metal forming technique with the following characteristics:

- Wide range of materials: suitable for a variety of metal materials, such as iron, steel, aluminum, copper, magnesium and so on.

- Flexible design: It can manufacture castings with complex shape and fine outline, and has high design freedom.

- Dimensional accuracy: Through accurate mold design and control, high dimensional accuracy can be obtained.

- Production efficiency: Suitable for mass production, suitable for large-scale manufacturing.

- Cost effective: For large or complex castings, the casting process is often more cost effective than other metal forming methods.

- Machinability: Castings after casting usually require further machining to meet end use requirements.

The main types of casting processes include:

- Sand casting: The use of sand as a molding material for the mold is the oldest and most common casting method.

- Metal mold casting: The use of metal materials (such as iron or steel) made of molds, suitable for mass production.

- Die casting: The rapid injection of molten metal into precision molds under high pressure is suitable for the manufacture of thin-walled, complex shaped parts.

- Precision casting: including investment casting, ceramic casting, etc., suitable for manufacturing high-precision, complex shape parts.

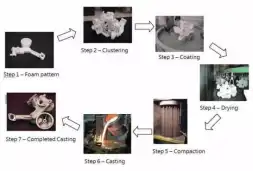

- Vanishing mold casting: A model made using a combustible material (such as foam) that burns away during the pouring process, leaving the casting behind.

- Centrifugal casting: Molten metal is poured into a rotating cast, using centrifugal force to distribute the metal evenly.

The choice of casting process depends on the design of the part, the material, the size, the precision requirements and the production batch and other factors. The casting process requires strict control of temperature, speed, pressure and other parameters to ensure the quality and performance of the casting

China vigor has rich experience in casting production process, through its high precision, high efficiency and high quality characteristics, to provide quality products, welcome to contact us to communicate your needs.

Welcome to contact Vigor for more detailed information, call us at 029 81161513 or email us at info@castings-forging.com