Knowledge

Ceramic Sand Application

We are a casting foundry in China. Recently we changed to use a better sand for castings, that's Ceramic Sand, instead of the Silica sand.

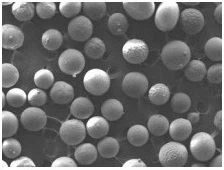

Ceramic sand was made of high quality bauxite by calcining, melting, granulating and screening processes. It's an environmentally friendly material for us now, has few dust and no silica dust hazards.

The benefits of ceramic sand to us:

1) This sand is in the shape of spherical, so it has better filling ability, but better air permeability when pouring, that's important to promote our cast iron and cast steel parts quality and avoid the potential deformation and defects.

2) As the higher temperature resistance (≥1800℃) and easier to be cleaned after pouring, it's helpful to make more complex structure cast iron and cast steel parts.

3) This sand has smaller expansion coefficient, so castings can have more precise dimensions.

China Vigor keeps continual improvement on production and cost down for customers.

|

|  |