Knowledge

Definition, Measurement Method, Significance and Influencing Factors of Yield Strength

1. Yield Strength

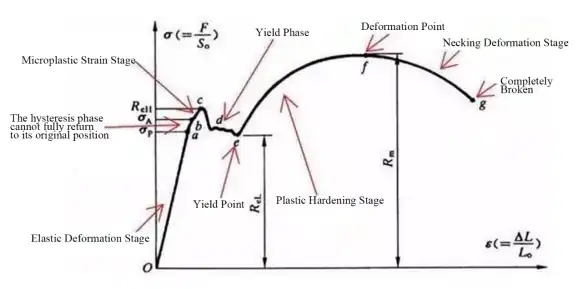

When the external force exceeds the elastic limit of the material, the material will undergo plastic deformation, that is, part of the residual deformation of the material will be retained after unloading. When the external force continues to increase to a certain value, the external force will not increase or decrease but the specimen will continue to elongate, which is manifested in the stress-strain curve is the appearance of a plateau or jagged peaks and valleys, which is called the yield phenomenon.

The force in the plateau phase is the yield force, the force before the first drop of the specimen when yielding is called the upper yield force, and the minimum force in the yield phase without considering the instantaneous effect is called the lower yield force. The corresponding strength is the yield strength, the upper yield strength, and the lower yield strength.

2. Determination of Yield Strength-

Metal materials without obvious yield phenomenon need to measure their specified non-proportional elongation strength or specified residual elongation stress, while metal materials with obvious yield phenomenon can measure their yield strength, upper yield strength, and lower yield strength. In general, only the yield strength is measured.

There are generally two methods for determining the upper and lower yield strength: the graphical method and the pointer method.

1) The graphical method

During the test, the force-chuck displacement diagram is drawn with an automatic recording device. It is required that the stress represented by the force axis ratio per mm is generally less than 10N/mm^2, and the curve should be drawn at least to the end of the yield phase. The constant force Fe of the yield plateau, the maximum force Feh before the first drop of force in the yield phase, or the minimum force Fel less than the initial instantaneous effect are determined on the curve.

Yield strength, upper yield strength, and lower yield strength can be calculated according to the following formula:

The yield strength calculation formula: Re = Fe/So, Fe is the constant force at yield.

The upper yield strength calculation formula: Reh = Feh / So, Feh is the maximum force before the first drop of force in the yield phase.

The lower yield strength calculation formula: Rel = Fel / So, Fel is the minimum force Fel that is less than the initial instantaneous effect.

2) The pointer method

During the test, when the needle of the force measuring disc stops rotating for the first time, the constant force or the maximum force before the first rotation of the pointer or the minimum force less than the initial instantaneous effect, the yield strength, the upper yield strength, and the lower yield strength correspond to the yield strength, the upper yield strength, and the lower yield strength, respectively.

3. Determination of upper and lower yield strength

The first peak stress before yield is judged to be the upper yield strength, regardless of the magnitude of the subsequent peak stress.

If there are 2 or more minima stresses in the yield stage, the first minimum stress is rounded off, and the smallest of the remaining minima is taken as the lower yield strength. If there is only 1 minimum, the lower yield strength is taken.

A platform appears in the yield stage, and the platform stress is judged to be the lower yield strength. If there are multiple platforms and the latter is higher than the former, the stress of the first platform is taken as the lower yield strength.

The lower yield strength must be lower than the upper yield strength

4. The meaning of yield strength -

The traditional strength design method takes the yield strength as the standard for plastic materials, and stipulates the allowable stress [σ] = σys/n, and the safety factor n is generally taken as 2 or greater, and for brittle materials, the tensile strength is used as the standard, and the allowable stress [σ] = σb/n, and the safety factor n is generally taken as 6.

Yield strength not only has direct application significance, but is also a rough measure of certain mechanical behaviors and process properties of materials in engineering. For example, the yield strength of the material is increased, and it is sensitive to stress corrosion and hydrogen embrittlement; The yield strength of the material is low, the cold working formability and welding performance are good, and so on. Therefore, yield strength is an indispensable and important indicator in the properties of materials.

5. Factors Affecting Yield Strength-

The intrinsic factors that affect the yield strength are: binding bond, structure, structure, and atomic nature. If we compare the yield strength of metals with those of ceramics and polymers, we can see that the influence of bonding bonds is fundamental. From the perspective of the influence of microstructure, there are four strengthening mechanisms that affect the yield strength of metal materials, namely, solution strengthening, deformation strengthening, precipitation strengthening and diffusion strengthening, grain boundary and subcrystalline strengthening. Among them, precipitation strengthening and fine-grain strengthening are the most commonly used means to improve the yield strength of materials in industrial alloys. Among these strengthening mechanisms, the first three mechanisms increase the strength of the material while reducing the plasticity, and only the refinement of grains and subcrystals can increase both strength and plasticity.

The external factors that affect the yield strength are: temperature, strain rate, stress state. With the decrease of temperature and the increase of strain rate, the yield strength of the material increases, especially the body-centered cubic metal is particularly sensitive to temperature and strain rate, which leads to the low-temperature embrittlement of steel. The influence of the state of stress is also important. Although yield strength is an essential indicator that reflects the intrinsic properties of a material, the yield strength value is different depending on the stress state. What we usually call the yield strength of a material generally refers to the yield strength when it is stretched in one direction.