Knowledge

Effect of Ultrasonic Quenching on the 42CrMo4 Steel Mechanics Properties and Microstructure

Ultrasonic quenching is to heat the quenched parts to the quenching temperature and properly keep warm, and then put them into the quenching tank with ultrasonic vibration to cool to achieve the quenching of the workpiece. Quenching is a key process to improve the strength and toughness, and the quenching process in the quenching cooling medium (water, oil, etc.) is generally divided into three stages: membrane boiling, bubble boiling, and convection heat exchange.

Among them, the bubble boiling is the most important stage, because the workpiece is in the rapid cooling stage, it should be ensured that the internasal temperature zone of the workpiece is in the bubble boiling stage of quenching. At the same time, the cooling rate should be greater than the critical cooling rate, so that the quenched steel structure can be transformed to the direction of martensite. In the conventional quenching and cooling process, the gas film in the high-temperature zone is difficult to crush even under intense stirring conditions.

After the introduction of the ultrasonic field, due to the "cavitation" effect of the ultrasonic wave in the medium, the resulting high-pressure shock wave impact ruptures the gas film and quickly enters the bubble boiling stage, which significantly increases the cooling intensity of the whole temperature zone.

As a common alloy structural steel, 42CrMo4 has high strength and toughness, no obvious tempering brittleness, high fatigue limit and resistance after quenching and tempering treatment, and good low-temperature impact toughness. Meanwhile, it is generally used to manufacture shafts, gears and connecting rod parts with large cross-sections. The heat treatment process has been relatively mature, but the quenching process is still susceptible to the influence of factors such as the quenching cooling medium and the cross-section thickness of the parts, and it is easy to produce cracks after water quenching, especially the workpiece with a large difference in cross-sectional thickness, which is very easy to crack when water quenching.

When oil quenching is adopted, due to the low cooling capacity, the large cross-section 42CrMo4 steel can not be hardened, resulting in the low qualification rate of its mechanical properties. In this paper, ultrasonic wave is introduced into the quenching and cooling process of 42CrMo4 steel, which improves the quenching intensity of the quenching cooling medium, and provides a reference for the research and application of 42CrMo4 steel quenching process.

2. Experiment materials and methods

2.1 Experiment materials

The chemical composition of the 42CrMo4 steel forgings used in the test is shown in Table 1.

Table 1 The Chemical composition of the 42CrMo4 (Quality Score) (%)

|

Elements |

C |

Mn |

Si |

S |

P |

Cr |

Mo |

|

Standard (EN 10083-3—2006) |

0.38~0.45 |

0.60~0.90 |

≤0.40 |

≤0.035 |

≤0.025 |

0.90~1.20 |

0.15~0.30 |

|

Measured |

0.42 |

0.77 |

0.29 |

0.010 |

0.019 |

1.14 |

0.224 |

In order to study the quenching process for 42CrMo4 steel parts with large cross-section, the forgings were processed into round specimens of φ90mm × 150mm by machining.

2.2 Experimental Principle and Methods

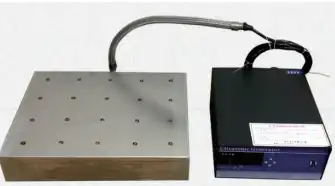

Figure 1 shows the ultrasonic quenching device, in which the power of the ultrasonic power generator is adjustable at 0~1500W.

a) Ultrasonic Generators

b) Application Status

Figure 1 The Ultrasonic Quenching Device

In the quenching process, the ultrasonic wave with a frequency of 28kHz is introduced into the ultrasonic transducer through the ultrasonic power generator, and the transducer converts the electrical oscillation pulse signal transmitted by the ultrasonic generator into high-frequency mechanical vibration, and the quenching sample is placed in the center of the quenching tank, and the position is relatively fixed to reduce the test error.

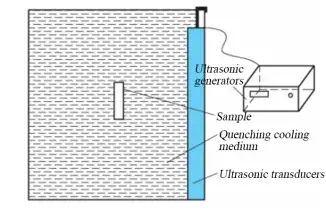

The sample is heated with TC15L-12 ceramic fiber muffle furnace, and the furnace meets the requirements of Class III furnace (±10°C) and Type D instrument specified in GB/T30825-2014 "Heat Treatment Temperature Measurement". The specific heat treatment process curve is shown in Figure 2, and the process requirements are shown in Table 2

Figure2 42CrMo4 Steel Heat Treatment Process Curve

Table 2 Quenching process requirements for 42CrMo4 steel

|

Sample Number |

Quenching Cooling Medium |

Whether or Not to Add Ultrasound |

Power/W |

|

1 |

20 °C water |

Yes |

1500 |

|

2 |

20 °C water |

No |

/ |

|

3 |

20 °C oil |

Yes |

1500 |

|

4 |

20 °C oil |

Yes |

1000 |

|

5 |

20 °C oil |

Yes |

500 |

|

6 |

20 °C oil |

No |

/ |

After heat treatment, samples were taken at 1/2 radius for metallographic structure observation and mechanical property testing. 1 group of specimens (2 tensile specimens, 2 impact specimens, 1 metallographic specimen) were taken for each specimen.

3 Experimental Results and Analysis

3.1 Effect of ultrasonic quenching process on mechanical properties

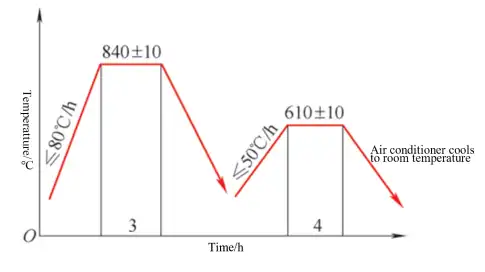

Figure 3 shows the mechanical properties of 42CrMo4 steel after quenching by different processes. This can be seen in Figure 3.

Figure3 The Mechanical Properties of 42CrMo4 Steel After Quenching by Different Processes

The tensile strength (Rm) and yield strength (Rp0.2) of the samples after oil quenching are lower than those of water quenching, but the elongation (A), section shrinkage (Z) and impact absorption energy (KV) are greater than those of water quenching, and with the increase of ultrasonic power, the tensile strength and yield strength gradually increase, while the elongation, section shrinkage and impact absorption energy gradually decrease.

3.2 Effect of ultrasonic quenching process on microstructure

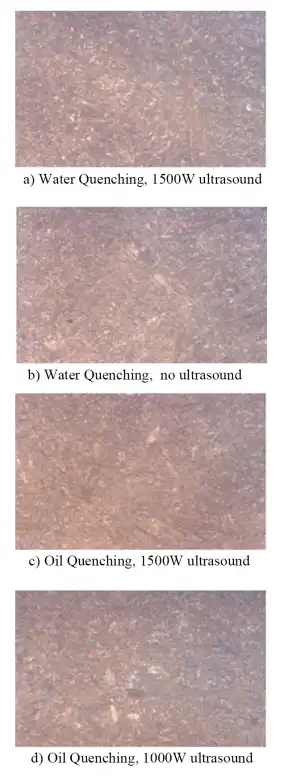

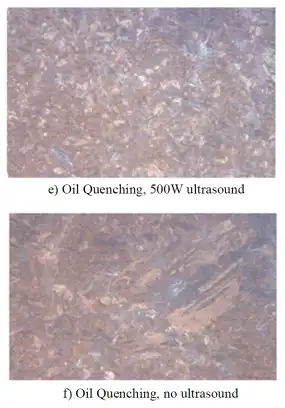

Figure 4 shows the microstructure of 42CrMo4 steel after quenching by different processes.

As can be seen from Figure 4, the introduction of ultrasonic waves has a significant effect on the microstructure of 42CrMo4 steel after quenching. The ultrasonic-assisted water quenching structure is tempered sostenite, as shown in Figure 4a. The structure of conventional water cooling is tempered soxhlet + a small amount of ferrite, and the grain is coarser than that of Figure 4a, as shown in Figure 4b. The structures under different powers of ultrasonic-assisted oil quenching were tempered sostenite + granular bainite + ferrite, but with the decrease of ultrasonic power, the content of granular bainite and ferrite gradually increased and the microstructure distribution became more and more uneven, as shown in Fig. 4c~e. The structure of conventional oil cooling is coarse tempered sostenite + partially granular bainite + ferrite, and the structure is very uneven, and the content of granular bainite and ferrite is greater than that of ultrasonic-assisted oil quenching, as shown in Figure 4f.

Figure 4 The Microstructure of 42CrMo4 steel After Quenching by Different Processes

Because 42CrMo4 steel is a sub-eutectic steel, compared with eutectic steel, the curve of the austenite isothermal transition diagram shifts to the left, the stability of the supercooled austenite is low, the gestation period is short, and a large cooling rate is required in the quenching critical transition temperature zone, otherwise it is easy to have non-martensite transformation due to insufficient supercooling.

Moreover, its oil viscosity and cross-section of the sample are both large, the cooling capacity is low, and the "nose tip" position of the austenite isothermal transition curve cannot be completely avoided during quenching, and the steel cannot be hardened, so the problem of bainite will occur due to insufficient cooling rate after quenching. After ultrasonic waves are introduced into the quenching cooling medium, the cooling capacity of the quenching cooling medium increases, and the cooling rate increases, which will promote the martensite transformation. With the increase of ultrasonic power, the content of bainite and ferrite gradually decreases, and when the ultrasonic power increases to 1500W, the cooling effect is close to that of water quenching.

4 Conclusion

1) Compared with conventional oil and water quenching, the tensile strength and yield strength of 42CrMo4 steel after heat treatment can be improved by adding ultrasonic, but the elongation, shrinkage after fracture and shock absorption energy are reduced.

2)In the process of ultrasonic oil quenching, with the increase of ultrasonic power, the cooling rate gradually increases, the tensile strength and yield strength gradually increase, while the elongation, post-fracture shrinkage rate and impact absorption energy gradually decrease. Meanwhile, the content of granular bainite and ferrite in the tissue gradually decreases, and the structure is more uniform.

|

元素路径:

|

字数统计 |

|