Knowledge

Gear Shaft Processing, Precision Control and Enhancing Transmission Efficiency

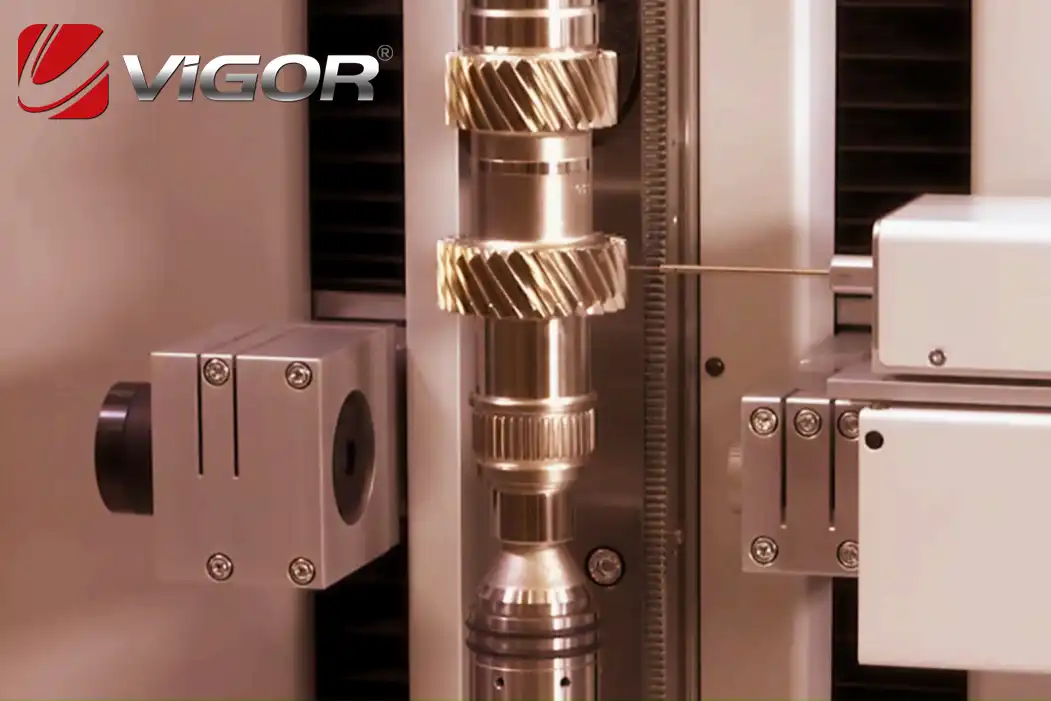

In the operation of various mechanical equipment, gear shafts, as key components of the transmission system, directly affect the overall efficiency and stability of the machinery. Different mechanical equipment have diverse working conditions and performance requirements, and conventional standard gear shafts are difficult to fully meet these needs. Therefore, customized gear shaft processing has emerged as a key solution to unlock higher transmission efficiency and more reliable working conditions.

Precise Customization to Meet Diverse Demands

Customized gear shaft processing can produce gear shafts with precise dimensions, materials, and precision based on the specific requirements of different equipment. From small electronic devices to large industrial machinery, Vigor Gear, with its professional technology and rich experience, tailors exclusive gear shafts for all types of equipment. For example, in the automotive manufacturing industry, gear shafts are customized according to the power requirements and transmission design of different vehicle models to ensure efficient and stable power transmission and a smooth driving experience.

Advanced Technology Ensures Precise Manufacturing

1. Precision CNC Machining: Vigor Gear uses advanced CNC machines to achieve high-precision cutting and processing. During the manufacturing process, precise programming control ensures that the dimensional errors of the gear shafts are kept within an extremely small range, guaranteeing that the dimensions and shapes of the gear shafts closely match the design requirements and laying a solid foundation for improving transmission efficiency. For instance, in the processing of gear shafts for aviation engines, the precise operation of CNC machines ensures the reliability of the gear shafts during high-speed and high-load operation.

1. Stringent Inspection Process: After the gear shafts are processed, Vigor Gear employs advanced inspection technologies such as laser measurement and camera measurement to conduct comprehensive inspections of the dimensional accuracy, surface roughness, and tooth profile error of the gear shafts. Any minor deviations cannot escape the "sharp eyes" of the inspection equipment. Only gear shafts that fully meet the design standards can proceed to the next stage, ensuring product quality from the source and avoiding transmission failures caused by dimensional deviations.

1. Scientific Heat Treatment Process: Based on different materials and application scenarios, Vigor Gear formulates scientific and reasonable heat treatment plans. Through heat treatment processes such as quenching, tempering, and carburizing, the material and mechanical properties of the gear shafts are improved, enhancing their hardness, strength, wear resistance, and fatigue strength. This enables them to better adapt to high-load and high-speed operating environments and extend their service life.

Customization Advantages Enhance Comprehensive Benefits

1. Significantly Improved Transmission Efficiency: Customized gear shafts can precisely match the equipment requirements, achieving more accurate transmission ratios and optimized working efficiency. In industrial automation production lines, customized gear shafts ensure smoother coordination among components, reducing energy loss, improving production efficiency, and lowering production costs.

1. Enhanced Reliability and Maintainability: Since the gear shafts are custom-made for the equipment, maintenance and replacement are more convenient. When gear shafts wear out or malfunction, suitable replacement parts can be quickly found, reducing equipment downtime and minimizing production losses caused by equipment failures. At the same time, the high quality and stability of customized gear shafts also reduce the failure rate during equipment operation, enhancing the overall reliability of the equipment.

1. Quick Delivery and Precise Service: Vigor Gear has a professional team and efficient production processes, enabling it to provide customers with a fast delivery cycle. Additionally, from the product design stage, it offers comprehensive technical support and precise services, promptly adjusting and optimizing based on customer feedback to ensure that the final product fully meets customer expectations.

Technological Innovation Leads Industry Development

With the rapid advancement of technology, gear shaft processing technology is constantly evolving. Vigor Gear actively introduces advanced manufacturing technologies such as CNC technology, laser processing technology, and 3D printing technology. The wide application of numerical control technology has realized the automation and intelligence of the processing process, greatly improving processing efficiency and precision; laser processing technology can achieve fine processing of gear shafts, meeting the processing requirements of some special shapes and high precision; 3D printing technology provides a new way for the manufacturing of complex structure gear shafts, shortening the product development cycle and reducing the development cost.

In the future, Vigor gears will continue to deeply explore the field of gear shaft processing, constantly explore and innovate, providing customers with more efficient and reliable gear shaft processing customization solutions with more advanced technology, higher quality products and more considerate services, helping to improve the performance of mechanical equipment in various industries and promoting the industrial development to a new height.

If you have any question, demand, new parts development or improve your supply chain, please feel free to contact us info@castings-forging.com