Knowledge

Low Pressure Casting Principles and Applications

1. Principle

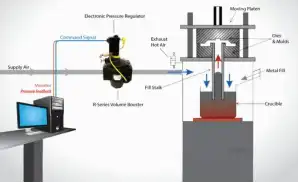

Low-pressure casting is a method of filling the cavity with liquid metal under pressure to form castings. In the casting process, the compressed air into the sealed crucible (containing liquid metal), so that the liquid metal surface by a certain gas pressure. Under the action of this pressure, the liquid metal along the rising liquid tube bottom-up through the gate smoothly into the casting cavity. When the liquid metal fills the cavity, the pressure is maintained for a certain period of time, so that the casting solidifies under the pressure, and then the pressure is lifted, so that the liquid metal that has not solidified in the ascending tube flows back into the crucible.

2. Equipment Composition

Crucible

This is the container for storing the metal liquid, usually made of heat-resistant material, such as graphite crucible or ceramic crucible. Its shape and size are designed according to the production volume of the castings and the amount of liquid metal required. For example, for the mass production of small castings, a relatively small crucible may be used, while for large castings, a crucible with a larger volume is required to ensure a sufficient supply of liquid metal.

Liquid Lift Tube

The liquid-raising tube is the channel that connects the crucible to the mould and guides the liquid metal into the mould. The material of the tube needs to have good resistance to high temperature and erosion of the liquid metal, and is generally made of ceramic or special metal materials. Its inner diameter and length are determined according to the shape and size of the casting. If the casting is high, the lift tube needs to be long enough to ensure that the liquid metal can rise smoothly to the top of the mould.

Moulds

The casting pattern can be sand, metal or moulded shell. Sand casting cost is low, suitable for complex shapes, single piece or small batch production of castings; metal casting has high dimensional accuracy and good heat dissipation properties, suitable for mass production of castings with high dimensional accuracy requirements. For example, in the low-pressure casting of automobile engine block, metal casting is often used to ensure the dimensional accuracy and internal quality of the cylinder block.

Sealing system and pressurising device

The sealing system is to ensure the pressure environment inside the crucible and prevent gas leakage. The pressurisation unit provides a stable compressed air pressure, which can be adjusted according to the requirements of the casting. Typical pressures are in the range of 0.02 - 0.07 MPa, which allows the liquid metal to rise smoothly and fill the mould.

3. process characteristics

Smooth mould filling

As the liquid metal is slowly rising into the casting mould under low pressure, compared with gravity casting, it can effectively avoid the liquid metal in the filling process to produce splash, involved in gas and other defects. For example, when casting thin-walled, complex shaped aluminium alloy castings, low-pressure casting can ensure that the liquid metal is evenly filled into all corners of the cavity, thus ensuring the integrity and quality of the castings.

High casting quality

Low-pressure casting can solidify under pressure, which helps to compensate for shrinkage, and can effectively reduce defects such as shrinkage holes and shrinkage loosening inside the casting. Moreover, due to the smooth filling process, the castings have a denser and more uniform organisation. Taking the casting of aluminium alloy parts in the aerospace field as an example, the parts produced by low-pressure casting have high mechanical properties, which can meet the harsh conditions of use.

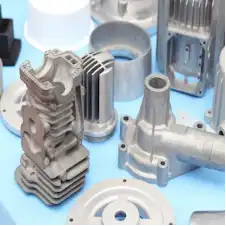

Wide range of application

It can be used for casting various alloy materials, such as aluminium alloy, magnesium alloy, copper alloy and so on. And it can produce castings with complex shapes and large differences in wall thickness. For example, it can cast electronic equipment radiator with thin-walled fins and thick-walled mounts, and the use of low-pressure casting can ensure that different wall thicknesses can be well formed.

4. Areas of application

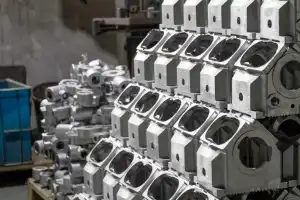

Automotive industry

Automotive engine block, cylinder head, wheel hub and other parts are many low-pressure casting process. Aluminium alloy cylinder, for example, low-pressure casting can produce light weight, high strength, good heat dissipation performance of the cylinder, in line with the requirements of automotive lightweight and high performance.

Aerospace field

It is used to manufacture some structural parts and components on the aircraft, such as landing gear parts, wing connectors and so on. These parts have very high requirements for material performance and quality, and low-pressure casting can provide high-quality castings to meet the safety and performance standards of aerospace.

Electronic equipment industry

Produces heat sinks, shells, etc. for electronic equipment. For example, some high-performance computers use low-pressure cast aluminium alloy heat sinks for their CPU coolers, which can effectively dissipate heat while ensuring the dimensional accuracy and appearance quality of the product.

Welcome to contact Vigor for more detailed information, call us at 029 81161513 or email us at info@castings-forging.com