Knowledge

Pre-coated Sand Casting (Shell Mold Casting) Application

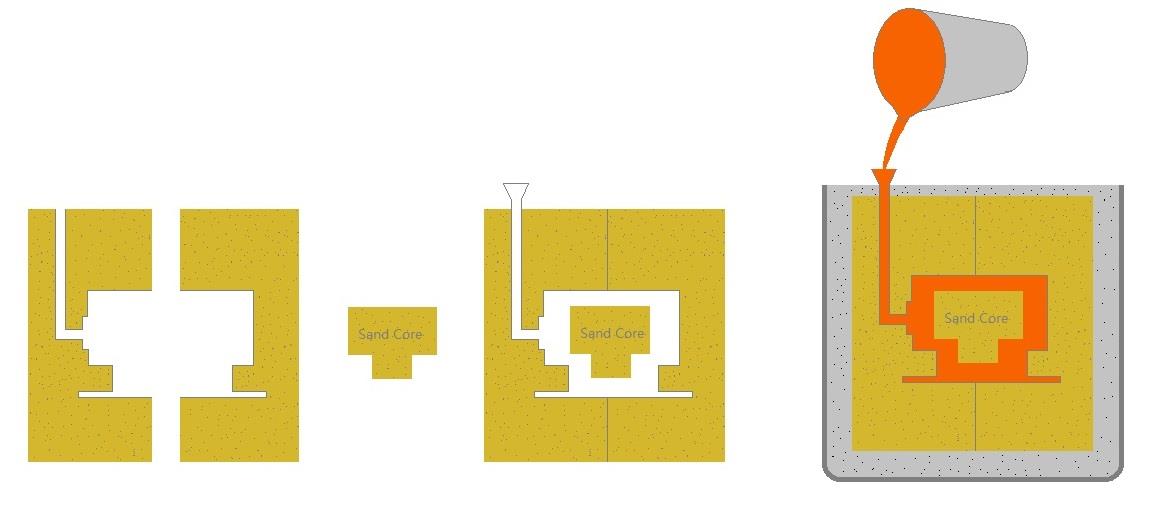

In fact, it’s a kind of sand casting, but different and an improved with the traditional sand casting. The sand was coated a layer of resin before making the sand shells, then the sand will be injected into steel mould by a special machine, named Core Shooting Machine.

The steel mould with sand inside will be sintered to get a complete sand shell. Heating temperature was set depend on the different wall thickness and volume of the sand shell.

Pre-coated sand shells have the same function with traditional manual molding shells, but it has more smooth cavity surface and it’s stronger, so we can get the parts with better surface and the best geometrical tolerance in all sand casting. By this technology the complicated structure of products become easier, drop sand defect was solved, fewer manual production procedures and more dense & micro mesh pre-coated sand can make the most stable quality.

This technology is suitable to make the ferrous metal castings with regular quantity demand and high surface quality request. Large quantity & fast delivery projects become controllable.

Dimensional accuracy is absolutely superior to any common sand casting and resin sand casting

Tolerance can meet: ISO 8062 CT8 – CT10

Surface roughness can meet: Ra (μm) 12.5–18.

Geometrical tolerances are the best in all sand casting, so we can also save lot of cost on machining.

|  |