Knowledge

The Main Difference Between Lower Bainite and High Carbon Martensite

In the field of materials science, lower bainite and high carbon martensite are two important metal microstructures, which have significant differences in microstructure characteristics, mechanical properties, and application fields. This article will detail the main differences between these two microstructures.

I. Microstructural Characteristics

The difference between lower bainite and high-carbon martensite in microstructure is first reflected in their morphology and structure.

Lower bainite:

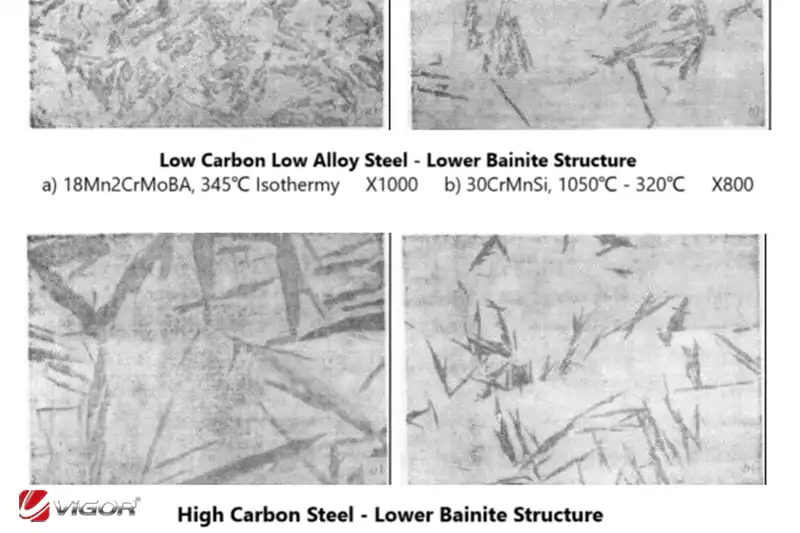

Lower bainite usually forms in the lower temperature range of the bainite transformation zone. Its morphology is black needle-like or bamboo leaf-like, and these needle-like or bamboo leaf-like structures show a certain angle distribution under a microscope. Lower bainite is a mixed structure composed of carbon-saturated lamellar α-ferrite (ferrite) and ε-carbides precipitated within it. Under an electron microscope, it can be observed that the carbides in this structure are fine and dispersed, and are neatly arranged along the direction at an angle of 55° to 60° to the long axis of the ferrite.

The formation of lower bainite is a semi-diffusion type phase transformation process. This means that during the phase transformation, the diffusion of carbon atoms in austenite is restricted to a certain extent. As the temperature decreases, the diffusion of carbon atoms in austenite becomes difficult, but they can still undergo short-range diffusion in ferrite. This formation mechanism gives lower bainite its unique microstructure and properties.

High-carbon martensite:

In contrast, high-carbon martensite is a single-phase structure with a plate-like morphology. It is a supersaturated solid solution of carbon in α-Fe, and its substructure is twinned. Under a microscope, high-carbon martensite appears as uniformly distributed dark black needle-like structures, which typically intersect at 60°angles.

The formation of high-carbon martensite is a non-diffusive phase transformation process. In this transformation, the diffusion of carbon atoms in α-Fe is almost completely inhibited, so the carbon atoms in high-carbon martensite exist in a supersaturated form in the ferrite lattice. This formation mechanism endows high-carbon martensite with extremely high hardness and strength, but poor plasticity and toughness.

II. Mechanical Properties

The main differences in mechanical properties between lower bainite and high-carbon martensite mainly lie in strength, toughness, hardness and notch sensitivity, etc.

Submerged Bainite:

Submerged Bainite exhibits high strength and toughness, with relatively low notch sensitivity. This combination of mechanical properties makes it outstanding when subjected to impact loads and alternating stresses. Additionally, submerged bainite has a relatively low transition temperature between ductility and brittleness, which enables it to maintain good toughness even in low-temperature environments.

The balance of strength and toughness of the lower bainite is mainly attributed to its unique microstructure and formation mechanism. The fine carbide particles are dispersed and distributed in the ferrite matrix, which plays a role in dispersion strengthening and enhances the strength. Meanwhile, the continuous distribution of ferrite and the uniform arrangement of carbides are conducive to the improvement of toughness.

High-carbon martensite:

High-carbon martensite has extremely high hardness and strength, but its plasticity and toughness are relatively poor. High-carbon martensite has a relatively high brittleness and is also highly sensitive to notches and cracks. Therefore, in scenarios where it needs to withstand impact loads and alternating stresses, high-carbon martensite may not be an ideal choice.

The high hardness and strength of high-carbon martensite mainly result from the supersaturated solid solution of carbon atoms and the twin substructure. The supersaturated solid solution of carbon atoms leads to lattice distortion and thereby enhances hardness. Meanwhile, the twin substructure increases strength by the accumulation and hindrance of dislocations. However, this microstructure also leads to the reduction of plasticity and toughness.

III. Application Domains

Due to the differences in mechanical properties between lower bainite and high-carbon martensite, there are also significant differences in their application fields.

Lower bainite:

Lower bainite is widely used due to its excellent comprehensive mechanical properties in applications that require resistance to impact loads and alternating stresses, such as automotive parts and mechanical engineering components. In these scenarios, the high strength and toughness of lower bainite can effectively withstand impact loads and alternating stresses, thereby extending the service life of equipment.

For instance, in the automotive industry, some high-end models of vehicles have adopted the lower bainite structure for their bearings and gears. This structure not only possesses high strength and toughness, but also can effectively resist impact loads and alternating stresses, thereby prolonging the service life of the components and enhancing the safety and reliability of the vehicles.

High-carbon martensite:

High-carbon martensite is widely used in situations that require high stress and high wear resistance, such as cutting tools, molds, bearings, etc. In these applications, the high hardness and strength of high-carbon martensite can effectively resist wear and deformation, thereby prolonging the service life of equipment.

In the field of tool manufacturing, high-carbon martensite is one of the indispensable materials. Due to the fact that tools need to withstand huge cutting forces and wear during use, the material must possess extremely high hardness and wear resistance. High-carbon martensite precisely meets these requirements, with its hardness typically reaching above HRC60, and even higher. This enables high-carbon martensite tools to perform exceptionally well when cutting hard materials, maintaining sharpness and durability for a long time.

IV. Comparative Analysis of Specific Examples

To further illustrate the differences between bainite and high-carbon martensite, the following provides a comparative analysis through specific examples.

Applications in Automotive Components:

In the automotive industry, lower bainite is widely used in the manufacturing of key components due to its excellent comprehensive mechanical properties. Besides the bearings and gears mentioned earlier, lower bainite can also be used to manufacture components such as engine connecting rods and crankshafts. These components need to withstand large impact loads and alternating stresses during operation, and the high strength and toughness of lower bainite can effectively meet these requirements.

In contrast, the application of high-carbon martensite in automotive components is relatively rare. However, in some special circumstances, such as certain high-stress parts in engines (such as valve seat rings, valve guides, etc.), high-carbon martensite microstructure may also be adopted to enhance their wear resistance and durability.

Applications in Tool Manufacturing:

In the field of tool manufacturing, high-carbon martensite is one of the indispensable materials. Due to the fact that tools need to withstand huge cutting forces and wear during use, the material must have extremely high hardness and wear resistance. High-carbon martensite precisely meets these requirements, and thus is widely used in the manufacturing of various tools (such as turning tools, milling tools, drills, etc.).

Although the lower bainite also possesses certain hardness and wear resistance, due to its more balanced comprehensive mechanical properties (i.e., both high strength and toughness), it is less applied in the manufacturing of cutting tools. However, in some cases where both the toughness and wear resistance of the cutting tool need to be considered (such as when cutting certain difficult-to-machine materials), lower bainite may also become a potential option. But it should be noted that in such cases, special heat treatment processes may be required to optimize the microstructure and properties of lower bainite to meet the usage requirements.

V. Conclusion

There are significant differences between lower-bainite and high-carbon martensite regarding their microstructure characteristics, mechanical properties, and application fields. Lower bainite has excellent comprehensive mechanical properties (high strength and toughness), and is suitable for applications that withstand impact loads and alternating stresses; while high-carbon martensite is suitable for applications that withstand high stress and high wear due to its extremely high hardness and strength. In practical applications, we need to select the appropriate microstructure type based on specific usage requirements and working conditions to ensure the performance and safety reliability of the equipment.

If you have any question, demand, related parts development or improve your supply chain, please feel free to contact us info@castings-forging.com