Knowledge

Types and Characteristics of Transmission Shafts in Reducers

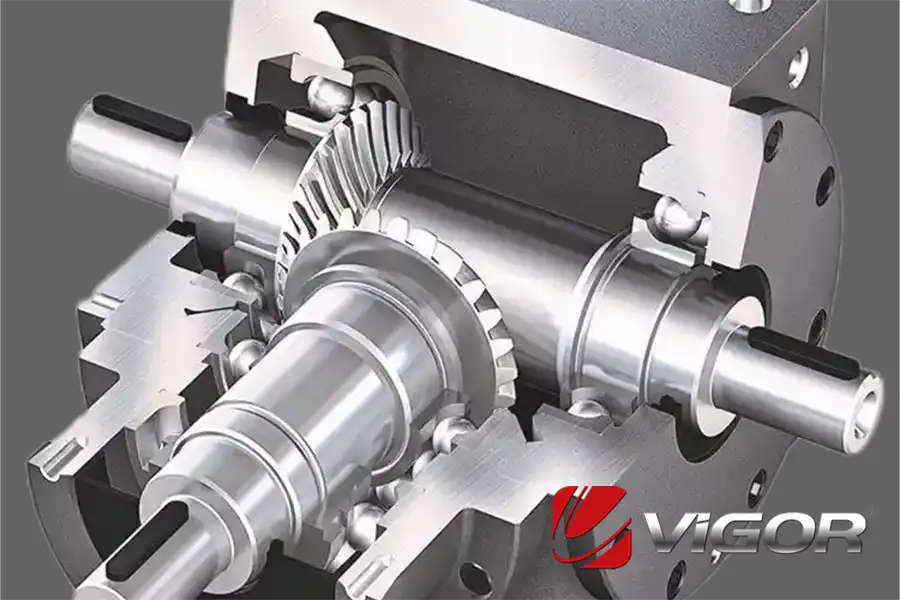

The transmission shaft of a reducer is an indispensable key component in mechanical transmission systems. It comes in various types, each with its unique functions and features, and is widely used in all kinds of mechanical equipment. The following is a detailed introduction to the types of transmission shafts of reducers, including their functions and characteristics:

The drive shaft: The drive shaft serves as a bridge connecting the power source (such as a motor or engine) to the input end of the reducer. It is responsible for efficiently and stably transmitting the rotational power generated by the power source to the interior of the reducer. The drive shaft design typically requires high strength and rigidity to ensure stable transmission performance even under high-speed rotation and heavy loads. Additionally, the material and processing accuracy of the drive shaft directly affects its service life and transmission efficiency.

Output shaft: The output shaft is the final power output end of the reducer, directly connected to the driven mechanical equipment. After the speed reduction and torque increase effect of the internal gears of the reducer, the rotational speed of the output shaft is relatively low, but the torque is greatly increased, which is very suitable for driving load equipment that requires large torque. According to different application requirements, the material of the output shaft can be divided into two major categories: metal and plastic. Metal output shafts have high strength and wear resistance, and are suitable for heavy-duty environments; plastic output shafts are lightweight and low-cost and are suitable for light-duty environments. In addition, the shape of the output shaft is also diverse, such as D-shaped shafts, round shafts, double flat shafts, hexagonal shafts, pentagonal shafts, square shafts, etc. Users can customize according to the specific equipment interface.

Intermediate shaft: In multi-stage reducers or complex transmission systems, the intermediate shaft plays a crucial role. It connects the drive shaft and the output shaft, serving to transmit and convert power. The design of the intermediate shaft needs to consider factors such as the transmission ratio, torque distribution, and spatial layout to ensure the smooth operation and efficient transmission of the entire transmission system. High-quality intermediate shafts not only reduce energy loss but also effectively lower noise and vibration.

Idle shaft: Idle shafts are mainly used to change the direction or path of transmission and do not directly transfer power. Their presence makes the transmission system more flexible and adaptable to various complex installation environments and layout requirements. The design of idle shafts is relatively simple, but they are indispensable in the entire transmission system, especially in applications that require multi-directional transmission or have limited space.

In addition to the above basic types, the transmission shafts of reducers also give rise to various derivatives based on differences in structure and materials, each with its own characteristics:

Solid shaft: The solid shaft has a simple structure and is made of solid material throughout. It is suitable for transmitting relatively small power and torque. Its advantages include relatively simple manufacturing process, lower cost, and higher rigidity and strength. However, due to the uniform distribution of material, the solid shaft is relatively heavy and is not suitable for applications with strict weight requirements.

Hollow shaft: The interior of a hollow shaft is a hollow structure, typically used for transmitting larger torques. Compared with solid shafts, hollow shafts can significantly reduce weight while ensuring strength, thereby enhancing transmission efficiency. Additionally, the internal space of a hollow shaft can be utilized for fluid transmission, achieving multi-functional integration. Although the design and manufacturing process of hollow shafts are relatively complex, their superior performance makes them widely used in high-end transmission systems.

Telescopic shaft: A telescopic shaft is a type of drive shaft that can be adjusted in length. It is suitable for applications where the installation distance or load frequently changes. Through the design of the telescopic mechanism, the telescopic shaft can flexibly adjust its length within a certain range, thereby adapting to different working environments and equipment requirements. The application of telescopic shafts greatly enhances the flexibility and adaptability of the transmission system.

In addition, based on different materials, the drive shafts of reducers can be further classified into steel shafts, stainless steel shafts, alloy shafts, and aluminum shafts, etc. Steel shafts, with their excellent strength and durability, are the most commonly used material for drive shafts; stainless steel shafts, due to their outstanding corrosion resistance, are suitable for humid or corrosive environments; alloy shafts, through special material ratios, can provide higher strength and durability, and are suitable for high-load and high-precision applications; aluminum shafts, with their light weight and good thermal conductivity, are suitable for some low-load applications where weight is a concern.

When choosing a transmission shaft for a reducer, it is necessary to comprehensively consider various factors such as specific application requirements, working environment, and load characteristics to ensure that the selected transmission shaft can meet the actual working conditions and achieve the best transmission performance. Through scientific and reasonable selection and design, the transmission shaft of the reducer can provide stable and efficient transmission support for various mechanical equipment and ensure the reliable operation of the entire system.

If you have any questions, demand, related parts development or improve your supply chain, please feel free to contact us atinfo@castings-forging.com or call us at 008681127932