Knowledge

What is Precision Casting?

Definition

Precision casting refers to the general term for the process of obtaining precision-sized castings. Compared with the traditional sand casting process, the castings obtained by precision casting have more precise dimensions and a better surface finish. Its products are precise, complex and close to the final shape of the part. Can be used directly without processing or processing. It is an advanced process of near-net-shape. And it can be suitable for low quantity request orders.

It includes investment casting, ceramic casting, metal casting, pressure casting, and lost foam casting.

Precision casting Commonly used is investment casting, also known as lost wax casting. It is widely used for producing ferrous and nonferrous metal casting.

Basic Conception

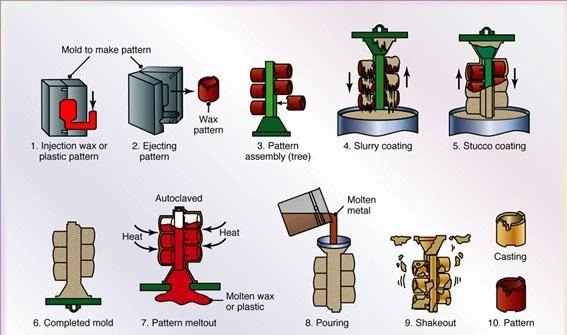

The investment mold is made by using a suitable investment material such as paraffin. The refractory coating and the refractory sand process are repeated on the investment mold. Hardened shell and dry. The internal melting mold is then melted off to get a cavity. The baked shell is obtained to get sufficient strength. The residual investment material is burned off and the desired metal material is poured. Solidification, cooling, shelling, sand cleaning. Thereby obtaining a high-precision finished product. Heat treatment and cold working and surface treatment according to product requirements.

Additionally, in both design and material choice of castings, Precision castings have huge freedom. It allows many types of steel or alloy steel for investment. So in the casting market, Precision casting is the highest quality casting.

Precision casting also faces a cost of molding and time. Each casting production requires a mold and one wax pattern. It will take more time and separate costs. So it is not a good cost-effective for low-quantity products.

Technological Process

Precision casting has many process steps, so it will take more time for each casting. If with a flow line to show. It is :

Waxing (wax mold)—repair wax—-wax inspection—-group tree (wax module tree)—shell (first paste, sand, re-slurry, finally Mould air drying)—Dewaxing (steam dewaxing)——-Mould roasting–chemical analysis–casting (casting molten steel in the mold shell)—-vibration shelling— Cutting and pouring of casting and pouring rod—-grinding gate—initial inspection (hairy inspection)—shot blasting—–machining—–polishing—finish inspection— Storage

The most important process are included in this picture. If you want to know more detailed information pls feel free to contact us.https://www.castings-forging.com/

Email: info@castings-forging.com