Knowledge

What is Squeezing Die Casting

In the modern manufacturing industry, the accuracy and performance of metal parts are increasingly required, and squeeze casting technology has emerged as a bridge connecting the advantages of casting and forging. This technology, with its unique process flow and excellent product characteristics, has brought revolutionary changes to the field of metal processing.

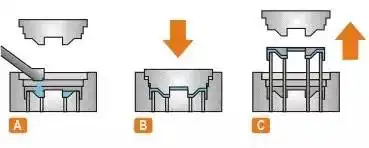

The basic process of squeezing die casting includes preheating the mold, injecting liquid metal, applying pressure, and curing and cooling. This process not only improves the heat flow rate, but also eliminates macroscopic and microscopic shrinkage pores, while limiting pore formation due to dissolved gases in the molten metal

Technical advantages:

1. Combine casting and forging: Squeeze casting is a technology that injects liquid metal into preheated molds and forms castings during the curing process through pressure, which combines the net shape of casting and the density of forging.

2. Improve material properties: Due to curing under pressure, squeezing die casting can effectively reduce pores and shrinkage holes, thereby improving the strength and ductility of the casting and improving the mechanical properties of the material.

3. Reduce defects: Compared with traditional casting, the contact between the metal and the mold wall during the squeezing die casting process prevents the formation of air gaps, thereby reducing defects caused by gas pores.

4. Precise control: By precisely controlling pressure and temperature, squeezing die casting can produce castings with high surface quality and high dimensional accuracy.

5. Environmentally friendly: Since almost no waste is produced, squeezing die casting is an environmentally friendly manufacturing process that meets the sustainable development requirements of modern manufacturing.

With the advancement of technology and the growth of market demand, squeezing die casting technology will continue to play an important role in improving product quality and expanding the scope of application. It not only improves the performance of castings, but also provides an efficient and energy-saving production method for the manufacturing industry.

Squeezing die casting technology has become an indispensable part of modern manufacturing industry with its excellent performance and wide application. By choosing vigor squeezing die casting, you chose a more efficient, environmentally friendly, and economical metalworking solution. Let's meet the new industrial revolution brought by squeezing die casting technology.

Welcome to contact Vigor for more detailed information, call us at 029 81161513 or email us at info@castings-forging.com