Knowledge

What is the most common casting process

The most common casting process is Sand Casting Process. Let CHINA VIGOR give a brief introduction of sand casting process.

1. Definition

The sand casting process involves pouring molten metal into a sand mould cavity, where it then cools and solidifies. After the metal has cooled, the mould is broken apart to remove the casting. Sand casting can produce complex net parts relatively quickly and cost efficiently compared to other processes. It's also a nearly 100% circular and extremely sustainable process with all the raw materials (sand and metal) being able to be reused.

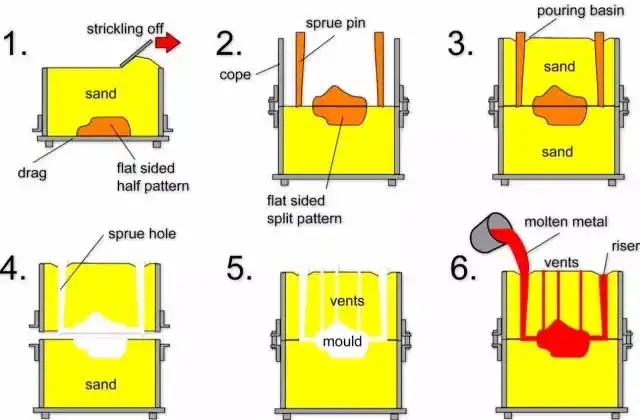

2. Process flow

3. Technical Feature

1. Suitable for making rough with complex shape, especially with complex inner cavity; Wide adaptability, low cost;

2. For some very poor plastic materials, such as cast iron, sand casting is the only forming process for manufacturing its parts or blanks.

3. Application

(1)Structural parts: Engine blocks, cylinder heads, pump housings, valve bodies, crankshafts, transmission cases, and manifolds

(2)Transportation: Automobile, aerospace, railways, and shipping

(3)Heavy industries: Marine diesel flywheels, through-hull nickel-aluminum bronze skin fittings, and tools used in heavy machinery and oil fields

(4)Defense: Defense industry

(5)Construction: Construction equipment's

(6)Agricultural equipment: Agricultural equipment's

(7)Mining equipment: Mining equipment's

(8)Plant machineries: Plant machineries

(9)Machine tools: Machine tools

(10)Decorative items: Sculptures and furniture pieces

4. Advantages

(1)Design Flexibility

The sand casting process empowers manufacturers with an exceptional level of creative freedom.

It allows them to create complex part geometries and intricate details that may be challenging to achieve with other manufacturing methods.

This flexibility is primarily attributed to the mold-making process, where patterns are formed in sand molds to create the desired shapes.

Another major advantage that the process offers when it comes to design flexibility is its adaptability to design modifications.

Unlike the permanent molds used in some other casting processes, sand molds can be easily altered or replaced to accommodate design changes.

The sand mold’s agility and flexibility are particularly advantageous in industries where product iterations and customization are common.

For example, consider the automotive industry, where engine components often require intricate designs to optimize performance and efficiency.

Within this industry, sand casting is often used to enable the production of complex engine blocks, cylinder heads, and intake manifolds with intricate cooling passages and precise geometries.

(2)Large Material Choice

Another significant advantage of sand casting is its compatibility with a diverse range of metals and alloys.

Sand casting offers manufacturers the flexibility to choose materials that best suit the application’s requirements.

The process can accommodate both ferrous metals, like iron and steel, and non-ferrous metals such as aluminum, copper, and brass.

Such versatility in material selection enables manufacturers to tailor the mechanical properties, corrosion resistance, and other characteristics of the final product to meet specific performance criteria.

Due to this freedom to use a variety of materials, the process is regularly used to create metal parts for a variety of applications, ranging from structural components and decorative elements to functional parts—all without compromising design integrity.

(3)Low Tooling Costs

Last but not least is sand casting’s cost-effectiveness when it comes to tooling.

Unlike some other casting processes that require expensive molds or dies, sand casting molds are typically made from inexpensive materials like sand, clay, and binders, making the process an attractive option for both prototyping and production runs.

Additionally, the process contributes to shorter lead times and faster turnaround because of the simplicity of the mold-making process it employs.

This agility enables manufacturers to quickly adapt to changing market demands and accelerate product development cycles without incurring substantial upfront costs.

Take for example the foundry industry, where rapid prototyping and low-volume production are common.

Within this environment, sand casting is often chosen to produce metal components.

Foundry managers can leverage inexpensive materials and better streamline the manufacturing processes by using this method, allowing them to offer more competitive pricing while maintaining high-quality standards.

As can be seen from the above, sand casting offers a trifecta of advantages—design flexibility, material versatility, and cost-effectiveness in tooling—making it one of the most popular casting methods for manufacturing metal components in various industries.

5. Disadvantages

(1)Rougher Surface Finishes

One of the most notable drawbacks of sand casting is its tendency to produce rough surface finishes on cast parts.

The texture of the sand mold transfers onto the final product, resulting in surface irregularities that may not meet the desired aesthetic or functional requirements of the project.

As a result of the rough surface finishes sand casting produces, additional finishing processes such as machining, painting, or sandblasting are often necessary to achieve the desired surface quality.

Post-casting finishing not only adds to production time and costs, but also introduces the potential for dimensional variations if not executed meticulously.

If we take, for example, the production of decorative or consumer goods where visual appeal is paramount, the rough surfaces resulting from sand casting would more than likely necessitate extensive finishing work to achieve the desired aesthetic quality.

In this instance, the additional processing that would be needed to meet surface finish requirements would almost certainly increase lead times and production costs, thereby potentially impacting overall project timelines and budgets.

(2)Lower Dimensional Accuracy

Compared to some other casting methods, such as investment casting and die casting, sand casting tends to exhibit lower dimensional accuracy and tighter tolerances.

Variations in the sand mold’s composition, moisture content, and compaction can lead to dimensional deviations in the final cast parts.

Achieving precise dimensional accuracy in sand casting requires careful attention to mold design, gating systems, and process parameters.

However, even with such meticulous planning and execution, there may still be inherent limitations to the achievable tolerances, particularly for intricate or large-scale castings.

Take automotive manufacturing, for example.

This is an industry where tight dimensional tolerances are crucial for ensuring the proper fit and functionality of engine components.

Therefore, the inherent dimensional variability of sand casting may pose steep challenges.

For example, parts such as engine blocks and transmission housings would most likely require additional machining operations to meet precise dimensional specifications if the sand casting process were used.

This would, in turn, add complexity, time, and cost to the production process, making sand casting disadvantageous.

(3)Higher Likelihood of Defects

Furthermore, sand casting is susceptible to a range of defects that can compromise the integrity and quality of cast parts.

Common sand casting defects include shrinkage, cold shuts, gas porosity, and sand inclusions.

The defects the process incurs often arise due to factors such as inadequate mold design, improper gating and risering, and variations in casting parameters.

Addressing such defects often requires extensive quality control measures, including non-destructive testing, visual inspections, and corrective actions such as re-melting and recasting.

If these measures are not taken, then the potential for higher production costs and lower performance and reliability will rise.

If we take a look at industries where safety and reliability are paramount (e.g. aerospace), we see that the presence of defects in critical components such as turbine blades or structural elements can have severe consequences.

That is why sand casting is often not a viable option for such applications.

However, if sand casting is used in these instances, then quality control protocols must be used to detect and mitigate any defects early on in the production process to secure a quality metal cast part.

As was just mentioned, despite its many advantages, sand casting is not without its challenges.

Problems such as rough surface finishes, lower dimensional accuracy, and the risk of defects must be contended with when employing the process.

However, with the proper understanding of these disadvantages, manufacturers can implement effective quality control measures that help mitigate risks and optimize the process to deliver higher-quality castings that meet the demands of diverse industries.

Welcome to contact us for more information, info@castings-forging.com, Tel: 029 81161513/10/31