Knowledge

Why do so many foundries use investment casting? There's a reason for that!

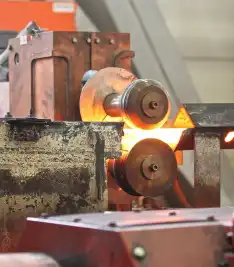

Investment casting, also known as lost wax casting, includes the processes of wax pressing, wax trimming, tree forming, slurry dipping, wax melting, metal casting and finishing. In lost wax casting, wax is used to make a wax mould of the parts to be cast, and then the wax mould is coated with slurry, which is the slurry mould. The clay moulds are dried and then baked to form ceramic moulds. After firing, all the wax moulds are melted and lost, leaving only the clay moulds. Generally, when the clay mould is made, the pouring hole is left open and the molten metal is poured through the pouring hole and after cooling, the required parts are made.

I. Casting method of investment casting

Hot type gravity casting

This is the most widely used form of casting, that is, the shell from the roaster after taking out, in the high temperature by casting. At this time the metal in the shell cooling slower, can fill the casting in the case of high mobility, so the casting can be a good copy of the shape of the cavity, improve the accuracy of the casting. However, the slow cooling of the casting in the hot mould will make the grain coarse, which reduces the mechanical properties of the casting. When casting carbon steel castings, the surface of slow-cooling castings is also easily oxidised and decarburised, which reduces the surface hardness, surface finish and dimensional accuracy of castings.

Vacuum Casting

The mould shell is put into the vacuum casting box, and the gas in the cavity is sucked out through the tiny holes in the mould shell, so that the liquid metal can better fill the cavity, copy the shape of the cavity, improve the precision of the castings, and prevent the defects of air holes and underpouring. This method has been applied abroad.

Pressure solidification

The shell is put into the pressure tank for casting, after the end, immediately close the pressure tank, to the tank into the high-pressure air or inert gas, so that the castings solidified under pressure, to increase the density of the castings. In foreign countries, the maximum pressure has reached 150 atm.4

2.The melt mould casting cleaning

Casting mould cleaning mainly has the following methods:

l From the casting to remove the shell;

l From the casting system to remove the casting;

l To remove the casting on the adherence of the shell refractory material;

l Casting heat treatment cleaning, such as in addition to the oxide skin, the end of the edge and cut the gate residue and so on.

3. The advantages of investment casting

Can form extremely complex parts

As a metal forming process, die casting can form extremely complex parts. Relative to die casting, sand casting, lost foam casting and other processes, investment casting can allow the highest complexity of parts.

Date stamps, text and internal spines can be moulded. Inverted buckles can be moulded. Complex pipes can be moulded. Using this feature, it is possible to use investment casting to combine parts originally processed through other processes into 1 part, thus simplifying the product structure, removing the assembly process, and achieving the purpose of cost reduction.

From another point of view, investment casting provides great freedom of design, extremely complex parts can be moulded by investment casting.

Good appearance quality

Melt casting castings have good appearance quality, low surface roughness, surface roughness up to Ra3.2um, the advantage is that, in some occasions, melt casting can remove the secondary machining process or painting and other surface treatment processes.

High dimensional accuracy

Relative to other casting process, investment casting casting dimensional accuracy is high. Of course, due to the complexity of the process of investment casting, affecting the casting dimensional accuracy of more factors, such as mould material shrinkage, deformation of the molten mould, the shell in the heating and cooling process of the line amount of changes in the alloy shrinkage and deformation of the casting during solidification, etc., so the general investment casting dimensional accuracy is high, but the consistency of the casting still need to be improved!

Material is not limited

Can melt mould casting of metal materials are not restricted, including carbon steel, alloy steel, heat-resistant alloy, stainless steel, precision alloys, permanent magnet alloy, bearing alloy, copper alloy, aluminium alloy, titanium alloy and ductile cast iron.

4.The disadvantages of investment casting

High cost

The biggest disadvantage of investment casting is that the cost is relatively high, because the process is cumbersome, the production cycle is long, at the same time, wax mould mould, paint, refractory sand and so on are cost. Therefore, investment casting is more suitable for medium and large quantities of products.

Simply replace the parts process with investment casting, the cost will be higher instead. If the investment casting is used for cost reduction, it is necessary to consider combining multiple parts, removing machining and so on.

Casting size can not be too large

Use of investment casting casting size can not be too large. The casting weight can be up to 1000Kg, beyond the weight of the casting is more difficult.

Affect the quality of investment casting too many factors, process quality control is more difficult. The shape of the castings are generally more complex, in the production of some of the original combination of several parts of the components, by changing the structure of the parts, designed to become a whole part and cast directly from the melt casting casting, in order to save processing time and metal material consumption, so that the structure of the parts is more reasonable.

Want to know more about casting information, Welcome to reach out us to communicate about your requirements. Please feel free to call us at 029 81161513 or email us at info@castings-forging.com