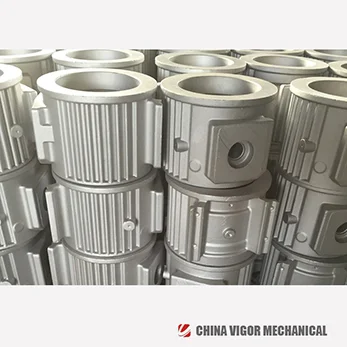

Aluminium Pump Housing

Production process: Metal Mould Casting

Material: Aluminium Alloy (material grade as per customer’s request)

Aluminium Pump Housing Introduction

When it comes to Aluminium Pump Housing, precision matters. Whether you're in the automobile manufacturing, industrial pump, or hydraulic equipment industry, you need pump housings that are not only durable but also meet the highest standards of performance. At VIGOR INNO-TECH Limited, we specialize in providing customized aluminium pump housings that meet the unique needs of OEMs, Tier 1 suppliers, and large-scale manufacturers.

Our expertise in metal mould casting allows us to produce high-quality product that help you achieve better product performance, reduce production costs, and ensure long-term reliability. In this product page, we’ll explore our products, their applications, and why choosing VIGOR as your supplier guarantees success.

Parameters

Understanding the technical specifications of our Aluminium Pump Housing is essential to ensuring it meets your operational needs. Here are the key parameters:

Material: Aluminium Alloy (material grade as per customer’s request)

Production Process: Metal Mould Casting

Weight Range: 0.5kg – 25kg (customizable)

Dimensions: Custom sizes available upon request

Surface Finish: Machined, Powder Coated, or Anodized (as per customer specification)

Tolerance: High-precision linear and geometric tolerances (as tight as ±0.05mm)

Certifications: ISO 9001, IATF16949

At VIGOR, we work closely with your team to ensure that the aluminium alloy used in your pump housing meets your specific mechanical property requirements, from tensile strength to corrosion resistance.

Working Process

Our products are crafted using a highly controlled metal mould casting process. This method ensures that each component is manufactured to exacting standards, minimizing defects such as porosity, shrinkage holes, and hot spots.

Design & Prototyping: We begin by working with your team to design the housing, ensuring it meets your exact specifications.

Mould Creation: A precision mould is created for casting, ensuring high repeatability and accuracy.

Casting: Aluminium alloy is melted and poured into the mould, ensuring uniform material distribution.

Precision Machining: After casting, the housing undergoes detailed machining to reach the required tolerance and surface finish.

Quality Control: Every product undergoes rigorous testing to ensure it meets all quality standards before being shipped.

Testing Equipment

To ensure the highest quality, we utilize advanced testing equipment to verify our Aluminium Pump Housings meet all necessary specifications. Our testing capabilities include:

X-ray Inspection: Detects internal defects such as porosity or cracks.

CMM (Coordinate Measuring Machine): Ensures dimensional accuracy and geometric tolerances.

Tensile Testing Machine: Verifies the mechanical strength of the aluminium alloy.

Surface Roughness Tester: Confirms the surface finish is within specification.

Leak Testing: Ensures the housing is free from leaks, crucial for hydraulic and pump applications.

Aluminium Pump Housing Applications

Our Aluminium Pump Housings are designed to meet the demanding requirements of a variety of industries, including:

Automobile Manufacturing: Used in water pumps, oil pumps, and fuel systems for enhanced vehicle performance.

Industrial Pumps: Ensures high durability and corrosion resistance in harsh environments.

Hydraulic Equipment: Provides strength and precision for hydraulic systems in heavy machinery.

Water Treatment Equipment: Ideal for pumps that undergo frequent exposure to water and corrosive chemicals.

Agricultural Machinery: Used in irrigation and water management systems, offering long-lasting performance.

Our aluminium pump housings are recognized for their lightweight properties, excellent corrosion resistance, and high thermal conductivity—key advantages in improving equipment efficiency and longevity.

Why Choose Us

Our Advantages

Technical Expertise: With decades of experience in metal mould casting, we understand how to optimize the casting process to avoid common defects like shrinkage holes and porosity.

Customization: We offer tailored solutions, from material selection to surface finishing, ensuring our products meet your specific requirements.

Precision: Our state-of-the-art equipment ensures that every housing meets tight tolerances, providing you with the high accuracy needed for critical applications.

Certifications: We comply with global quality standards, including ISO 9001 and IATF16949, ensuring you receive only the best products.

Logistics & Packaging

Our logistics team ensures prompt delivery, with packaging designed to protect your products during transit. We offer flexible shipping options and can accommodate urgent orders when necessary.

Our Factory

Based in an industrially developed area, our factory is equipped with advanced casting and machining equipment, allowing us to handle both large-scale production runs and complex custom designs. We prioritize environmental compliance, employing energy-efficient processes and sustainable practices wherever possible.

FAQ

1. What is the typical lead time for an order?

Lead times vary depending on the complexity of the product, but we typically deliver within 4 to 6 weeks. Expedited services are available upon request.

2. Can you provide samples for verification?

Yes, we offer samples for verification. Once you approve the sample, we can proceed with full production.

3. What certifications do you hold?

We are certified to ISO 9001 and IATF16949, ensuring our products meet stringent quality standards.

4. How do you handle quality issues?

We have a comprehensive quality assurance system in place. Should any quality issues arise, our team is dedicated to providing timely solutions and improvements.

5. What materials do you offer besides aluminium?

While aluminium is our specialty, we also offer a variety of other materials, including stainless steel and carbon steel, depending on your application needs.

Contact Us

Ready to boost the performance of your pumps with high-quality Aluminium Pump Housings? Contact us today to discuss your project needs or request a quote.

Email: info@castings-forging.com

Let’s work together to create long-term solutions that drive your business forward.

By choosing VIGOR INNO-TECH Limited for your Aluminium Pump Housing needs, you're ensuring high-quality products, on-time delivery, and a supplier partnership designed for long-term success. We look forward to supporting your next project!

hotTags : Aluminium Pump Housing,China, suppliers, manufacturers, factory, foundry, customized, buy, quotation, low price, high quality, high accuracy, high performance, free sample,accurate,OEM.